Adani Cement and Coolbrook to deploy world’s first commercial RotoDynamic Heater to advance cement decarbonisation

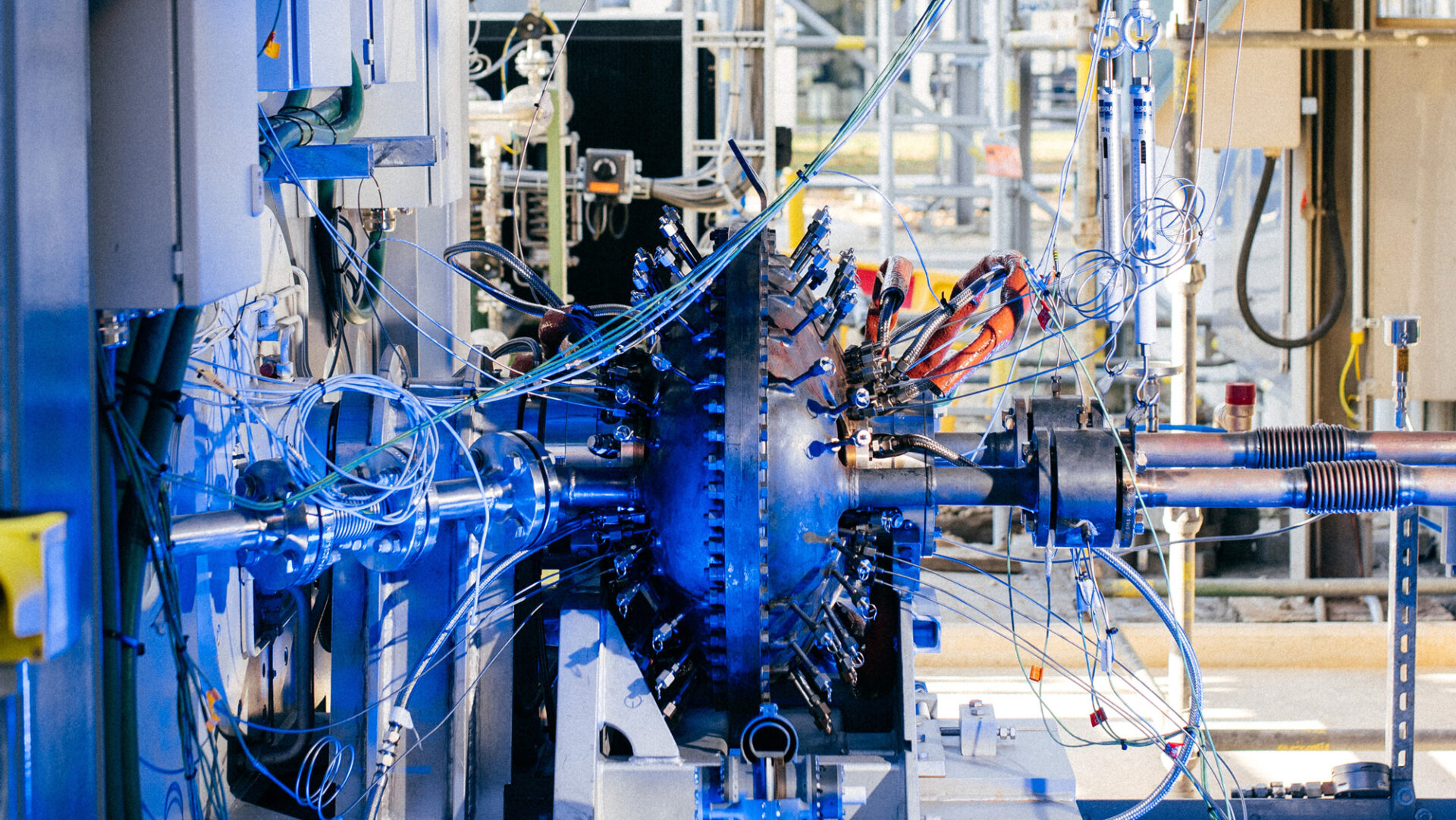

Adani Cement and Coolbrook have partnered to deliver the world’s first commercial deployment of Coolbrook’s RotoDynamic Heater™ (RDH™) at the Boyareddypalli cement plant in India. This groundbreaking project pioneers clean, electrified industrial heat powered entirely by renewables, marking a major step toward decarbonising global cement production.

For further information, please contact

Coolbrook

Lauri Peltola

Chief Commercial Officer

lauri.peltola@coolbrook.com

Helsinki, Finland, 12 November 2025: Adani Cement and Coolbrook announce their delivery agreement for the world’s first commercial deployment of the revolutionary RotoDynamic Heater™ (RDH™) technology to advance cement decarbonisation at the Boyareddypalli Integrated Cement Plant in Andhra Pradesh, India. This marks the first industrial scale deployment of Coolbrook’s RDH™ technology, advancing Adani Cement’s net-zero goals achievement by 2050 (validated by the SBTi) and Coolbrook’s goal of cutting 2.4 billion tonnes of annual CO₂ across heavy industry sectors globally.

This technology will decarbonise the calcination phase – the most fossil fuel-intensive stage of cement production. By providing clean heat to dry and enhance the heating value of alternative fuels, the technology enables a significantly higher substitution of fossil fuels with sustainable alternatives. This deployment is expected to directly reduce ~60,000 tonnes of carbon emissions annually with a potential to increase 10x in due course, marking a major step toward decarbonising cement manufacturing.

Critically, the RDH™ system will be powered entirely by Adani Cement’s large-scale renewable energy portfolio, ensuring that the industrial heat generated is completely emission free. This deployment demonstrates the real-world feasibility of clean, electrified industrial heat powered entirely by renewables. This positions Adani Cement to spearhead India’s emergence as the world’s clean manufacturing cement hub.

Mr Vinod Bahety, CEO – Cement Business, Adani Group, said: “The world’s first commercial deployment of Coolbrook’s RotoDynamic Heater™ within our operations marks a pivotal moment in our decarbonisation journey. This is a major leap towards achieving our net-zero goals. By integrating such cutting-edge electrification solutions into our cement production, we are accelerating the shift away from fossil fuels, reducing emissions at scale, enhancing the utilisation of clean energy sources, and setting a new standard for sustainable manufacturing. This ongoing partnership reflects our unwavering commitment to climate leadership and delivering long-term value through innovation and sustainability. This milestone underscores our legacy as pioneers and highlights our transformative actions towards becoming a global building materials solutions powerhouse. We are building a stronger eco-system of partners like Coolbrook along with our R&D investments.”

The project provides a strong and scalable use case for deep industrial decarbonisation with significant potential for replication. Coolbrook and Adani Cement have identified multiple follow-on opportunities for deploying RotoDynamic Technology across Adani Cement’s industrial operations and share an ambition to launch at least five additional projects within the next two years.

Going forward, RDH™ technology will play a pivotal role in decarbonising Adani Cement’s production, improve process efficiency, and accelerate the Company’s sustainability goals including improving AFR (alternative fuels and resource materials) usage towards 30% and increasing the share of green power to 60% by FY28. The first generation RDH™ will deliver hot gases at around 1000°C, which will facilitate drying of alternate fuels, making its utilisation greener and more efficient, representing a breakthrough in high-temperature electrification for cement production.

“Entering into the first industrial-scale project in the world with Adani Cement marks a transformative step for industrial electrification in one of the world’s most vital cement markets,” said Mr Joonas Rauramo, CEO of Coolbrook. “Our mission is to make RotoDynamic Technology a new industry standard for decarbonising hard-to-abate sectors. Together, we’re redefining how cement is produced – cleaner, more efficient, and ready for a net-zero future.”

Adani Cement’s broader sustainability leadership is reflected in it being among the four large-scale cement companies globally to have SBTi-validated net-zero targets and global collaborations including being the world’s first cement manufacturer to join the Alliance for Industry Decarbonisation (AFID), under IRENA.

About Adani Cement

Adani Cement is the building materials solutions business of the diversified Adani Group, comprising the iconic and most trusted cement brands Ambuja Cements and ACC. As the 9th largest cement producer globally, Adani Cement has ~107 MTPA of installed capacity and accounts for nearly 30% of the cement used in India’s housing and infrastructure projects. The Company offers a broad portfolio of building materials and solutions, ranging from all-purpose cement and concrete grades to specialty products designed for challenging applications. Backed by cutting-edge R&D centres and a commitment to sustainability, Adani Cement is the fourth large scale globally to have its net zero goals validated by the SBTi and has pioneered green and specialised concrete technologies and advanced additives to reduce the carbon footprint of construction. Adani Cement’s mission is to build a stronger nation by delivering quality, innovation, and reliability in construction materials, supported by extensive technical services and a customer-centric approach. For further information on this release, please contact: mitul.thakkar@adani.com

About Coolbrook:

Hailed as the key technology for industrial decarbonisation globally, Coolbrook is a transformational technology and engineering company on a mission to decarbonise major industrial sectors like petrochemicals and chemicals, iron and steel, and cement. Coolbrook’s revolutionary rotating technology combines space science, turbomachinery and chemical engineering to replace the burning of fossil fuels across all major industrial sectors. The technology has two main applications: RotoDynamic Reactor™ (RDR™) to reach 100% CO2 free olefin production, and RotoDynamic Heater™ (RDH™) to provide carbon-free process heating to iron and steel, cement and chemicals production. Once implemented at scale, the RotoDynamic Technology has the potential to reach temperatures of 1700°C and cut 2.4 billion tonnes (30%) of annual CO2 emissions in heavy industry. For more information, please visit www.coolbrook.com

Safe Harbour Statement

This press release contains forward-looking statements relating to Ambuja Cements Limited and ACC Limited’s future operations, performance, and financial outlook, which are based on current assumptions and expectations. These statements involve inherent risks and uncertainties that could cause actual results to differ materially from those anticipated. Factors such as changes in market conditions, economic developments, regulatory requirements, industry dynamics, and unforeseen circumstances may impact the company’s performance. Ambuja Cements Limited and ACC Limited undertake no obligation to publicly update or revise any forward-looking statements, whether as a result of new information, future events, or otherwise. For a detailed discussion of these risks, please refer to our filings with the Securities and Exchange Board of India (SEBI) and other relevant regulatory authorities.

Entering into the first industrial-scale project in the world with Adani Cement marks a transformative step for industrial electrification in one of the world’s most vital cement markets. Our mission is to make RotoDynamic Technology a new industry standard for decarbonising hard-to-abate sectors. Together, we’re redefining how cement is produced – cleaner, more efficient, and ready for a net-zero future.

Joonas Rauramo

CEO, Coolbrook